Our Craft

Authentic Japanese Dried Noodles

Whole Grain, Additive-Free, and Milled In-House.

At Kaneko Seimen, we believe that good noodles are the result of deliberate, thoughtful choices at every step of the process. For over 140 years, our company has stood by the philosophy that simple ingredients, handled with care, produce exceptional results.

As a Japanese food manufacturer with a long-standing heritage, we take pride in crafting dried noodles that reflect both tradition and innovation. Our focus is not only on flavor and texture but also on health, safety, and respect for nature. By managing everything in-house—from selecting wheat and milling flour to drying and packaging—we maintain complete control over quality and food safety.

Our factory is located in Nakai, Kanagawa Prefecture, where natural surroundings, clean water, and ideal climate conditions support our production. We incorporate the strengths of Japanese agricultural practices, food science, and engineering to deliver products trusted by customers at home and abroad.

Whether you’re preparing a meal for your family or sourcing high-quality noodles for export, Kaneko Seimen offers authenticity, reliability, and care in every strand.

Our Commitment to Honest Materials

- Japanese-Grown Wheat, Carefully Selected

-

At Kaneko Seimen, we believe that truly great noodles begin with truly great ingredients. That’s why

we use only wheat grown in Japan—sourced from domestic farms committed to sustainable practices and

consistent quality.

We select our wheat based on strict criteria: flavor, grain hardness, protein content, and moisture levels. This not only ensures a consistent and clean taste but also supports sustainable domestic agriculture and food security.

- Whole Grain for Flavor and Nutrition

- Our whole grain noodle offerings are made with flour that retains the bran, germ, and endosperm. These components provide dietary fiber, B vitamins, iron, and antioxidants. Whole grain flour also contributes a warm, slightly nutty flavor and a darker, richer appearance. Because whole grain oxidizes quickly, we mill our flour in-house daily to ensure it’s as fresh and flavorful as possible.

- Simple, Additive-Free Noodles

-

We also take pride in producing additive-free, clean-label noodles. We never use artificial

preservatives, colorants, bleached flour, or chemical enhancers. Our commitment to simplicity means

our noodles contain only the essentials: flour and water. This approach aligns with global demand for

natural, minimally processed foods, and reassures health-conscious consumers and business buyers

alike.

In addition, we carefully monitor allergens and cross-contamination risks. While our noodles contain wheat, we avoid the use of common allergenic additives, making our products suitable for a wide range of customers and applications.

By focusing on clean, high-quality Japanese ingredients and handling every step ourselves, we ensure that our noodles not only taste good—they reflect the values of Japanese food craftsmanship and integrity.

Precision Milling to Preserve Natural Flavor

- Low-Stress Milling with Japanese Technology

-

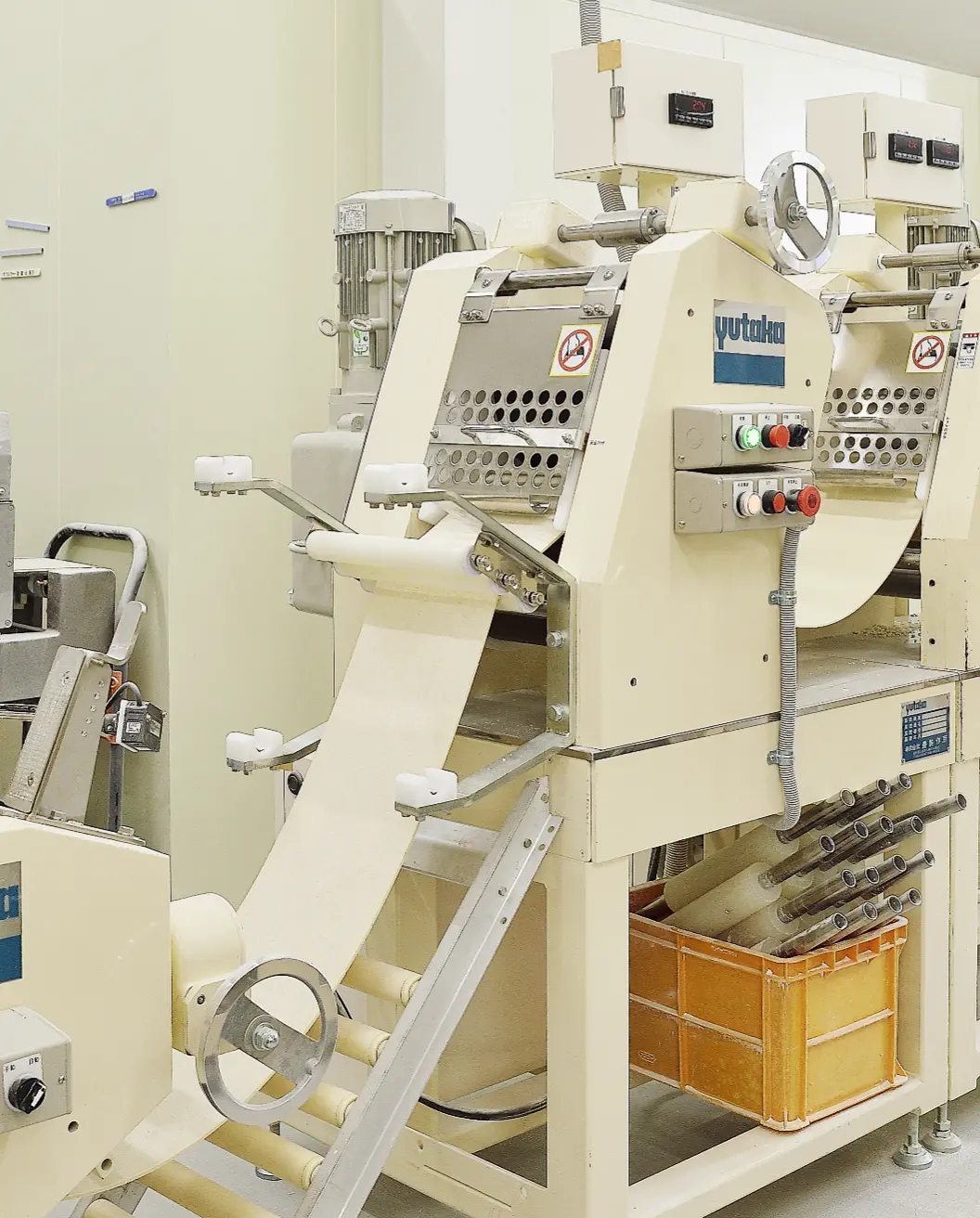

At Kaneko Seimen, we believe that the quality of flour defines the quality of the noodle. That’s why

we mill all of our wheat in-house, using a precision-controlled, low-stress milling system developed

by Yanagihara—a trusted Japanese manufacturer known for producing compact, high-performance flour

mills.

Unlike conventional high-speed, high-pressure roller mills used in industrial food production, our system operates at low temperature and low rotation speed. This allows us to process wheat gently, preserving the grain’s natural aroma, nutrients, and enzymatic activity. It also minimizes heat-induced oxidation, which can degrade flavor and shorten shelf life.

Fresh flour is milled daily in our factory to ensure maximum freshness and batch-specific consistency. This approach gives us full control over flour quality parameters such as particle size, moisture content, and protein balance—factors that directly affect dough elasticity, drying time, and noodle texture.

- Tailored Milling for Different Noodle Types

- The flexibility of our milling system also enables us to support small-batch production and rapid adaptation to different noodle types—whether it’s udon, soba, ramen, or pasta. By adjusting grind size and flour blend ratios, we can tailor the base flour to meet the unique demands of various markets and cooking methods.

Because our production is fully integrated, milling is not an outsourced step—it’s part of our craft. It

allows us to bridge the gap between field and factory, transforming carefully selected Japanese-grown

wheat into the foundation of a reliable, flavorful noodle.

We see milling not just as a process, but as a point of pride. By controlling every micron of flour we

use, we ensure that every strand of noodle carries the quality, freshness, and precision that Kaneko

Seimen stands for.

Integrated Production for Quality and Safety

-

Complete In-House Process,

from Flour to Packaging -

At Kaneko Seimen, we handle every step of production under one roof—from flour to final packaging.

This fully integrated system gives us complete control over quality, hygiene, and traceability, all of

which are critical for delivering reliable, high-performance Japanese dried noodles.

Once the flour is milled, it is immediately transferred to the dough mixing process. We use precision-controlled mixers that adjust hydration and mixing speed depending on environmental factors such as ambient temperature and humidity. This ensures dough consistency and elasticity are maintained across seasonal and regional conditions.

The dough is then extruded or sheeted and cut into uniform strands, depending on the noodle type. Whether we are producing udon, soba, ramen, or pasta, cutting settings are calibrated to preserve mouthfeel, rehydration balance, and cooking durability.

- Whole Grain for Flavor and Nutrition

-

Next comes drying—a process that is often underestimated, but is absolutely critical to noodle

quality. We dry our noodles slowly and at controlled temperatures to prevent surface cracking, flavor

loss, or structural breakdown. Proper drying stabilizes moisture levels, enhances shelf life, and

ensures that the noodle maintains its integrity when boiled.

Once dried, noodles are immediately packaged in a clean-room environment. Our packaging line is designed to prevent contamination and to preserve freshness. We also conduct regular visual inspections, metal detection, and weight checks to meet both domestic and international food safety standards.

Our facility operates under HACCP-based food safety management protocols, with daily documentation, traceability logs, and strict compliance controls. These measures ensure that our products not only meet Japanese regulations but are ready for export to regions with rigorous food import laws.

By consolidating the entire production cycle—from mixing and kneading to drying and final inspection—we eliminate variability and ensure stable quality, lot after lot. This consistency is what makes Kaneko Seimen noodles a trusted choice for foodservice operators, distributors, and consumers worldwide.

Built on Respect, Sustained by Integrity

- Craftsmanship and Honesty at the Core

-

At Kaneko Seimen, we believe that food is more than just nourishment—it is a reflection of values,

culture, and human connection. For over 140 years, we have upheld the philosophy that good food begins

with good intentions: to use honest ingredients, treat them with care, and pass them along with pride.

Our noodles are made with a mindset rooted in Japanese craftsmanship. We respect the nature of each raw material and refrain from altering it unnecessarily. This is why we never use artificial preservatives or chemical flavoring agents. We believe that simplicity is strength, and that flavor should come from the wheat itself—not from additives.

-

Partnering with a Global,

Health-Conscious Market -

In a world of increasing automation and mass production, we continue to value the small details. From

choosing Japanese-grown wheat to milling it ourselves, and managing every step of the process, our

approach reflects the Japanese concept of “shokunin kishitsu” (職人気質)—the spirit of dedication to one’s

craft.

We also recognize our role in supporting sustainable food systems and health-conscious consumption. By offering whole grain noodles, additive-free recipes, and transparent production practices, we meet the growing global demand for clean-label, naturally made foods.

More than anything, we are committed to earning long-term trust. We understand that importers, retailers,

and chefs choose partners based on reliability and consistency. That is why we focus not only on making

good noodles—but on being a good partner.

Kaneko Seimen is not just a manufacturer. We are a team of people who take pride in sharing the best of

Japanese food with the world, one noodle at a time.

Info

Learn More About Who We Are and What We Make

Want to take a closer look at our manufacturing standards and product lineup?

Explore our company background and the full range of our Japanese dried noodles.